Citation: Schätzle, Philip, Nicola Lang, and Peter Knittel. “Placement of Nitrogen‐Vacancy‐Centers in Diamond Through Chemical Vapor Deposition Growth Techniques.” physica status solidi (a) (2025): e202500730.

Authors: Philip Schätzle, Nicola Lang & Peter Knittel

Publication location: Physica status solidi (a) – Wiley Online Library

Date: 2025

DOI: https://doi.org/10.1002/pssa.202500730

Abstract:

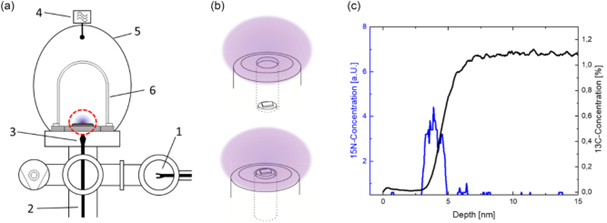

The positioning of nitrogen-vacancy (NV) centers is critical for quantum technologies such as quantum sensing and computing. NV incorporation during chemical vapor deposition growth can provide a defect-free, well-controlled environment, yielding high spin-coherence times and stable color centers. Various reactor designs that allow for controlled gas-switching have been developed, and process conditions have been optimized to achieve low growth rates, enabling placement of single NV centers or NV ensembles during growth or post-growth at defined depths and in specified regions. This is primarily achieved by fabricating delta-doped layers—nanoscale-thick dopant layers within the diamond. In addition to using the as-grown layers, these structures can be further processed by lithography or implantation methods to laterally position NV centers at a defined depth, even in complex diamond structures. Under suitable growth conditions, NV centers can also be positioned on prepatterned microstructures by preferentially forming delta-doped layers on defined facets. For lateral positioning on flat surfaces, a similar approach can localize NVs. This article describes and compares these methods and outlines future perspectives in the context of quantum technologies.